KRECA FR Profile

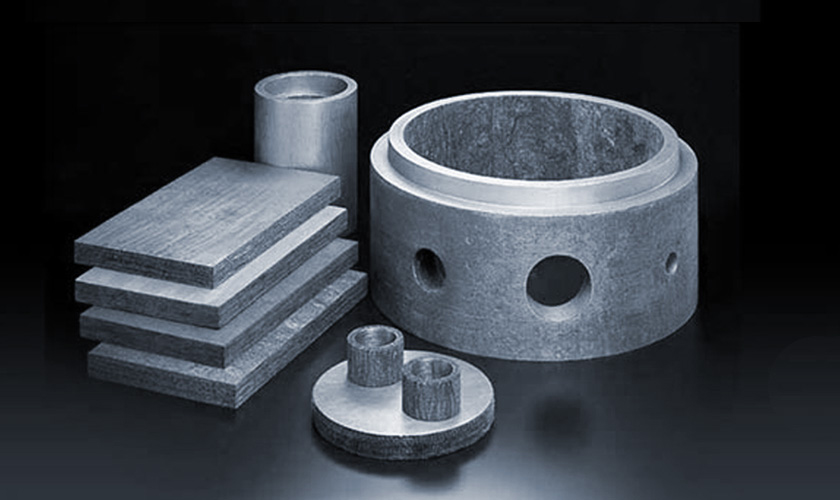

KRECA FR, which function as excellent insulation, are products for use in furnaces with high-temperature closed atmosphere. The graphitized carbon-fiber insulation is manufactured by forming carbon fiber felt into the desired shapes, such as boards, discs, and cylinders, with a small quantity of binder. We will meet and respond to the various needs of our customers’ desires about shapes of KRECA FR.

Examples of KRECA FR Shapes

Examples of KRECA FR Shapes

Main Usages or Applications

Features of KRECA FR

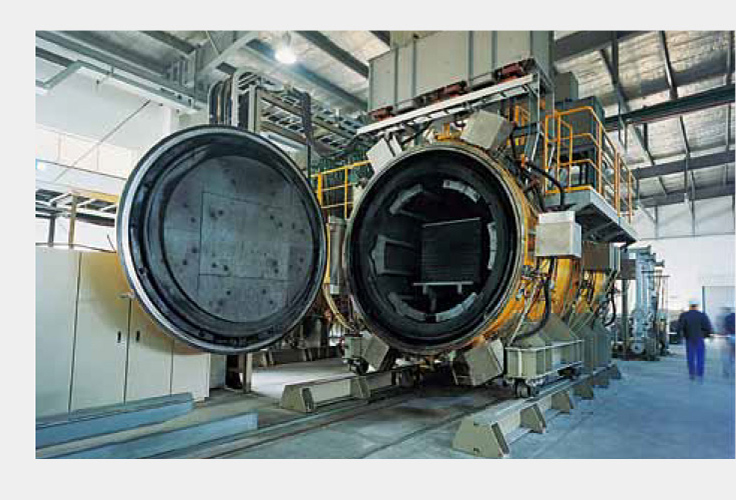

Large Sintering Furnace for Carbon-fiber Insulation

Large Sintering Furnace for Carbon-fiber Insulation

Installation Advantages

Our Products are Helping to Create the Products that Make Our World a Better Place to Live

Specifications of KRECA FR

Types and Grades

BAC may be classified into four grades based on average particle size

Typical Physical Properties and Characteristics

Typical Effects of Surface Treatments

Fiber Orientation | Thermal Conductivity | Impurities

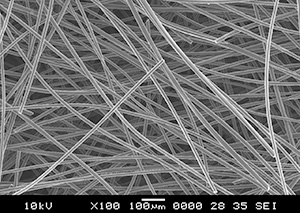

Appearance of the KRECA FR Surface

(parallel to laminated surface)

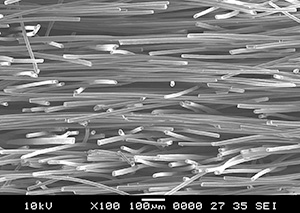

Appearance of the KRECA FR Surface

(perpendicular to laminated surface)

Average Thermal Conductivity (in vac.)

Impurities Contained in KRECA FR

Under an atmosphere of 1.33Pa | 50 mm thick pieces

Oxidation Resistance Characteristics

Improvement in Oxidation Resistance Feature by Surface Treatments

Difference in Oxidation between Types of Carbon Fiber

Pitch-based Carbon Fiber

Rayon-based Carbon Fiber

Examples of KRECA FR Usage

KRECA FR works both as frame protection and insulation for crystal-growth devices such as mono-crystalline silicon ingots, compound semiconductors, optical-fiber performs, quartz, sapphire ingots, etc.

Monocrystalline Ingot Puller

Multicrystalline Casting Silicons

PV Panels

Maximum Sizes

Maximum available sizes differ depending on thickness. Please feel free to contact us about details.